Circular Plastics

The Circular Plastics Chair is located on the Brightlands Chemelot Campus and focuses on providing polymer science for improved mechanical recycling as well as data science and systemic thinking for overall improved circularity of plastics. We are strongly involved in the Circular Engineering BSc of the Faculty of Science and Engineering, and a part of the Circular Chemical Engineering Department.

The chair is held by prof. Kim Ragaert and co-led by asst. professors Rudinei Fiorio, Ali Gooneie and Sin Yong Teng, each of whom coordinate one of the group's research lines and subgroups. We are a strongly collaborative group and host associated academics from key institutes: assoc. prof. Steven De Meester (UGent), assoc. prof. Marcel van Eijk (NTCP) and asst. prof. Milad Golkaram (TNO).

Projects

C-PlaNeT

MSCA-ITN-EJD C-PlaNeT - Circular Plastics Network and Training; funder: European Union's Horizon 2020 research and innovation programme under the Marie Sklodowska-Curie grant agreement (EU). In C-PlaNeT, 15 ESRs are working along the value chain and across different domains to realize a more circular economy for plastics.

Start date 01/01/2020

End date 31/12/2023

Multiflex

Multiflex is a TKI project in which we collaborate with NTCP and several industrial partners to investigate the quality of flexibles recycling after improved sorting.

Start date 01/02/2023

End date 31/01/2024

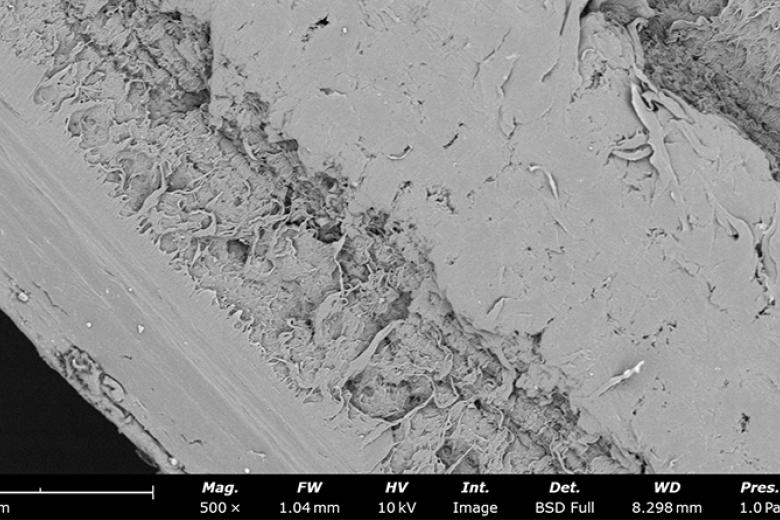

ESCR in recycled plastics

It is well-known that rHDPE does not perform well in environmental stress crack resistance (ESCR), but it is insufficiently understood how and why exactly these rapid failures occur for recycled plastics. In this PhD research, we are creating a macromolecular understanding of the mechanisms at work, to then provide solutions for this industrial challenge.

Start date 01/11/2021

End date 31/10/2025

CEFLEX

CEFLEX is a collaborative initiative representing the entire value chain of flexible packaging. They have developed a Quality Recycling Process for post-consumer flexible packaging and regularly run industrial-scale trials. The Circular Plastics Chair supports them with analysis of trial results, advice for product applications and updated Design for Recycling guidelines for flexible packaging.

Start date 01/10/2021

End date ongoing

CIRCULAR FoodPack

Circular FoodPack is a Horizon project led by Fraunhofer. It aims to enable the circular use of plastic packaging, addressing the most sensitive product category: food. The project investigates tracer-based sorting, additional pretreatment like de-inking and combinations of mechanical and dissolution-based recycling.

Start date 01/06/2021

End date 30/11/2024

INCREACE

This recently approved Horizon project aims for the increasing of recycled content in added value products for a resilient and digitized circular economy. It will start from 5 central business cases to identify and clear hurdles for PCR uptake in high-quality products. INCREACE not only considers all recycling technologies (mechanical, chemical and solvent-based), but also explores digital twinning and the building of circular societies.

SYSCHEMIQ

This recently approved Horizon project brings together a total of 20 partners from industry, business, knowledge institutes, educational institutions, and government in the Netherlands, Belgium, and Germany. Other European regions are eager to learn from the knowledge gained. The new project will start this year and continue through 2025. The goal is to reduce the use of oil and gas and start applying used plastic as a new raw material. The project team is compiling, developing and testing a blueprint of what a larger, cross-border region needs to make strides in raw materials and the energy transition, and ways to collaborate.

MoQuP-R

In the plastics recycling process flow, plastic waste quality monitoring is challenged by the lack of data, specification and standardization. MoQuP-R addresses quality monitoring along the mechanical recycling chain to validate existing quality models (RQ and QMRP). Collaboration with industrial partners and established research facilities also enables real-life simulation of proposed methods.

SuFIP-S

Standing for Sustainable and fire-safe plastics based on fully organic phosphorus-sulfur compounds, this project embraces a systematic, interdisciplinary approach to the degradation, processing and recycling of PP/FR plastics to provide a scientific basis for developing new PP/FR materials and increasing the quantity and quality of recyclate.

CLEANpack

This project aims to systematically analyze and improve advanced mechanical recycling technologies for closed-loop recycling of polyolefin-based food packaging. The project will provide an objective and unique scientific understanding of the potential of the most common advanced mechanical recycling options to achieve food-grade polyolefin recyclate.

DPI: PET-PLA

Although using PLA, a biodegradable polyester, is beneficial in reducing the impact of plastics discarded in the environment, it harms PET recycling. The project aims to clarify if certain additives and processes can reduce the effect of PLA in PET recyclates, increasing the sustainability of PET/PLA blends.

PlastiCycle 4.0

PlastiCycle 4.0 aims to incorporate quality-based recycling into cutting-edge sensing technologies polymer processing and digital modelling options. We emphasize on AI modelling to characterize feedstock quality interactions and physical/ chemical functionality to position the Dutch circular plastics industries at a competitive edge.

Check out Kim Ragaert’s TEDx talk Plastics Rehab

Kim Ragaert on the sense and nonsense of bioplastics

Circular Plastics: the challenges of plastic recycling

How can you turn plastic waste into new products? Professor of Circular Plastics Kim Ragaert and her team explain the most important challenges of plastic recycling.