Quickservices

- Up to 5000€, financed by researcher (budget number required);

- Up to one month runtime;

- Some examples: a simple prototype, a proof of concept, repair of a set-up;

- Technological Readiness Level 3.

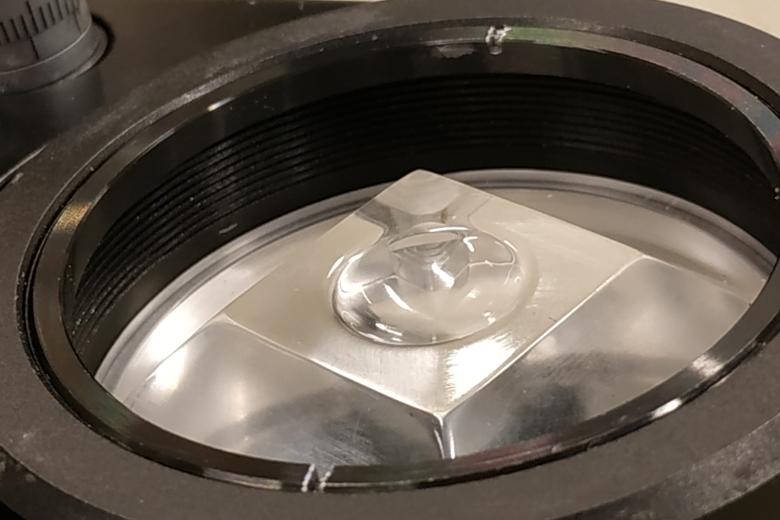

Optic lens to study porcine eye

The department of Ophtalmology reqested the design and fabrication of an optic lense to study the porcine eye. This work involved 3D milling of acrylate.

Lasercut LINK logo

MERLN institute requested the fabrication of a physical logo of the LINK programme. This work involved customized letter laser cutting from acrylaat and integration of blue LED strips.

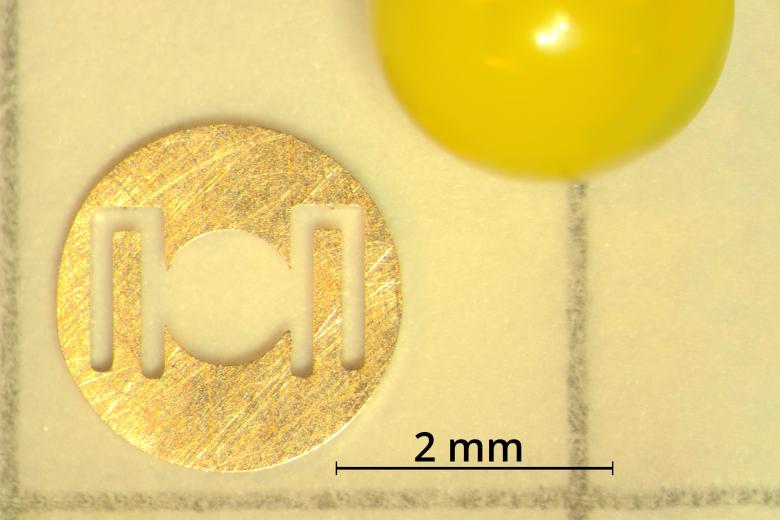

Miniature parts

M4I Nanoscopy in collaboration with HennyZ requested the fabrication of extremely small parts. In yellow you see the head of push pin. Using his magic hands, this part was machined by Paul Verjans.

Repair of spindle

MERLN requested the repair of of the rotary part of a particle grinder. Two broken blades were replaced by custom made new ones.

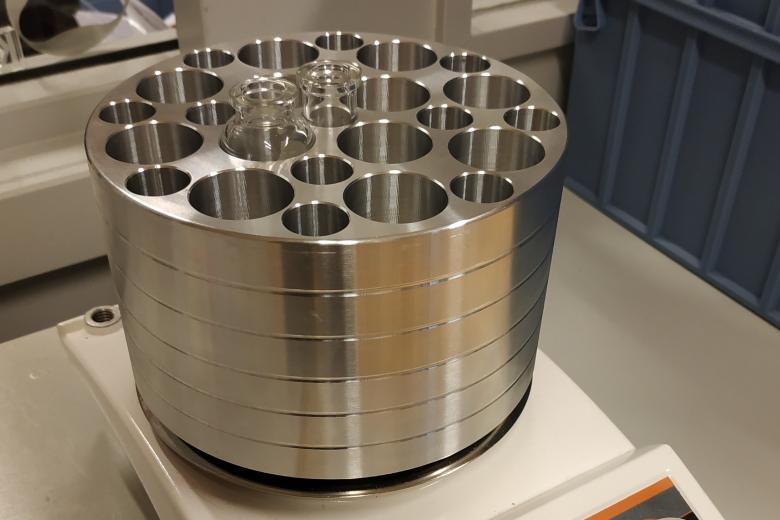

Holder to heat test tubes

The Faculty of Science requested a safe solution to heat up test tubes. An aluminium holder with good heat conductivity was designed and fabricated. This work involved turning and milling.

Trigger pulse generator

M4I Mass spectrometry requested the fabrication of an externally triggered device that creates a 100μs pulse at 5V DC. This work involved electronic design and assembly.

Display for brain slices

The Anatomy department requested the fabrication of a display for brainslices which can be stacked on top of each other for educative purposes.

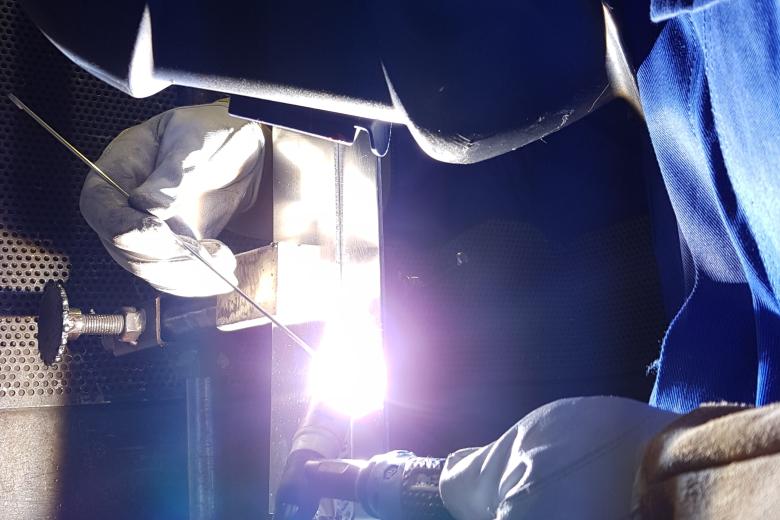

Welding repair

General welding jobs. For example: repair of animal cages and mounting a 360° camera platform to a harnas.