Research

The department's research mission is to create low-cost and user-friendly sensors that could replace the current state-of-the-art in sample analysis. Currently, industrial and medical samples are screened for the presence of targets, ranging from small molecules to microorganisms, by means of sophisticated, expensive devices or slow, laborious lab analysis.

The Sensor Engineering department aims at studying every aspect of the sensor engineering process including receptor synthesis and immobilisation, development and characterisation of read-out equipment and software engineering. The developed sensors can be used for application in a wide range of industrial sectors such as medical diagnostics, food safety or environmental screening.

Bio(mimetic) sensing

Biosensors are characterised by the biological recognition element they use to recognize their target. Over the past few decades, biosensors have evolved from something as simple as a canary in a coalmine to sense toxic gases to technologically advanced devices that continuously monitor e.g. blood glucose levels.

Although biosensor research has led to the development of several commercial enzymatic sensor applications, there are drawbacks associated with the use of natural receptors. Their limited stability in challenging environments (temperature, pH) makes it complex to integrate them into disposable sensor strips. Synthetic receptors that have a similar affinity for their target but are superior in thermal, mechanical, long-term and chemical stability can offer solutions.

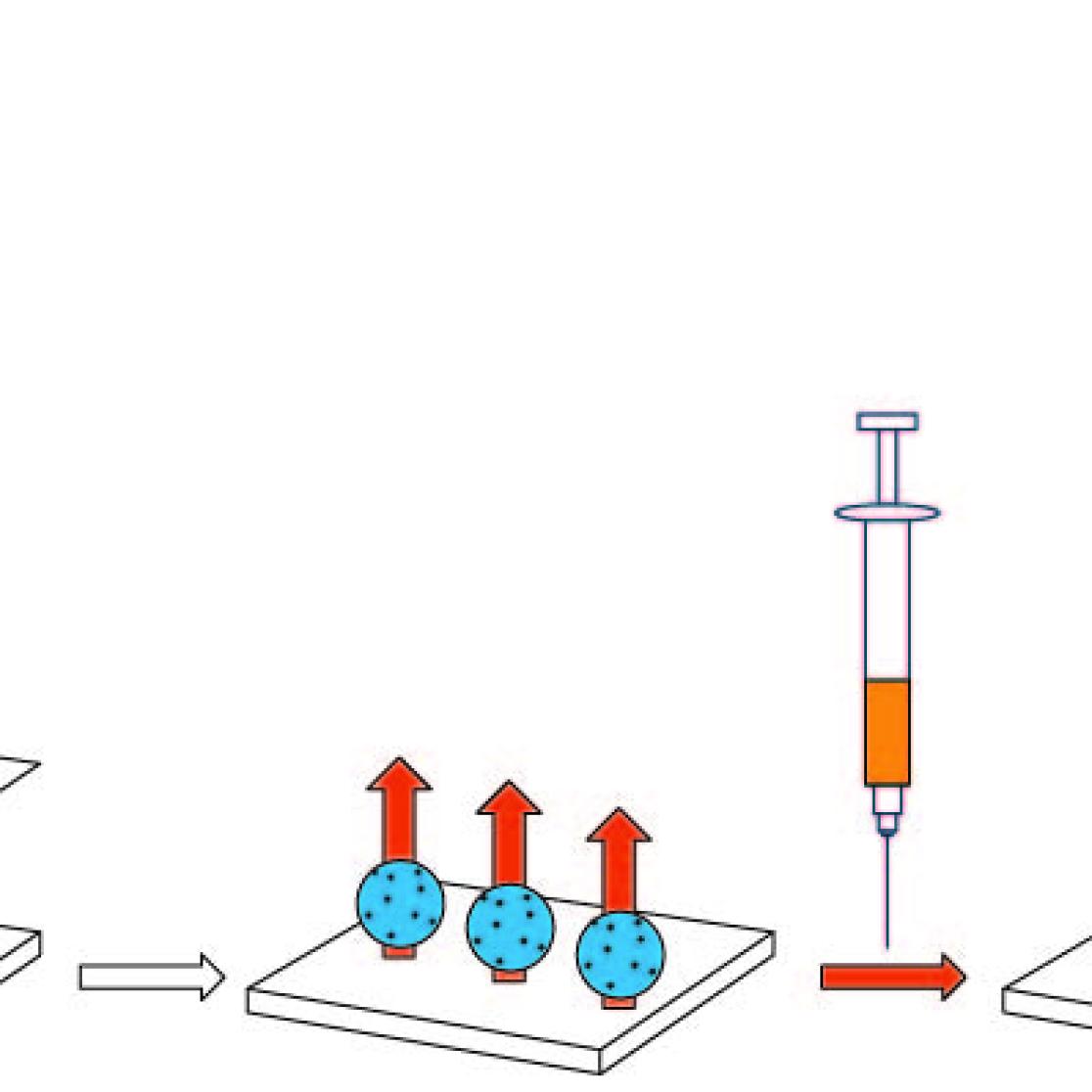

Therefore, the Sensor Engineering department has devoted a lot of research to the development of so-called molecularly imprinted polymers (MIPs) that can replace the antibodies or enzyme traditionally used in biosensors to create cheaper, more robust biomimetic sensors. MIPs have shown to be particularly suited for the detection of small molecules in aqueous solutions. The detection of larger entities, ranging from proteins to microorganisms or whole cells can be done in a similar way. Flat polymer layers are imprinted with the target and removed, creating a pattern of micron-sized molds on the surface of these so-called surface-imprinted polymers (SIPs).

Projects

CROSSMINDS

CROSSMINDS is an Interreg Flanders-Netherlands project with the aim of achieving a better match between the demand and supply of knowledge and the corresponding knowledge transfer to companies.

SABER PRINT

The project is aimed at investigating the potential impact of smart (bio)-sensors on the process industry of the future.

Food Screening EMR

The project will focus on three separate domains: the integration of sensor technology into the agricultural value chains, building food and health claims to improve product placement and investigating new cultivation techniques that yield healthier food crops.

SenSpores

SenSpores is an Interreg VI Germany-the Netherlands project (ERDF) aimed at developing novel sensor strategies for the rapid, on-site detection of fungal and bacterial spores in liquid food products.

PFAS-resolve

The PFAS-resolve partnership aims to further develop a novel portable biosensor and phytoscreening technology to measure PFAS chemicals on-site through fast and cost-effective screening.