Brightlands Circular Space focuses on integrated approach to entire plastic value chain

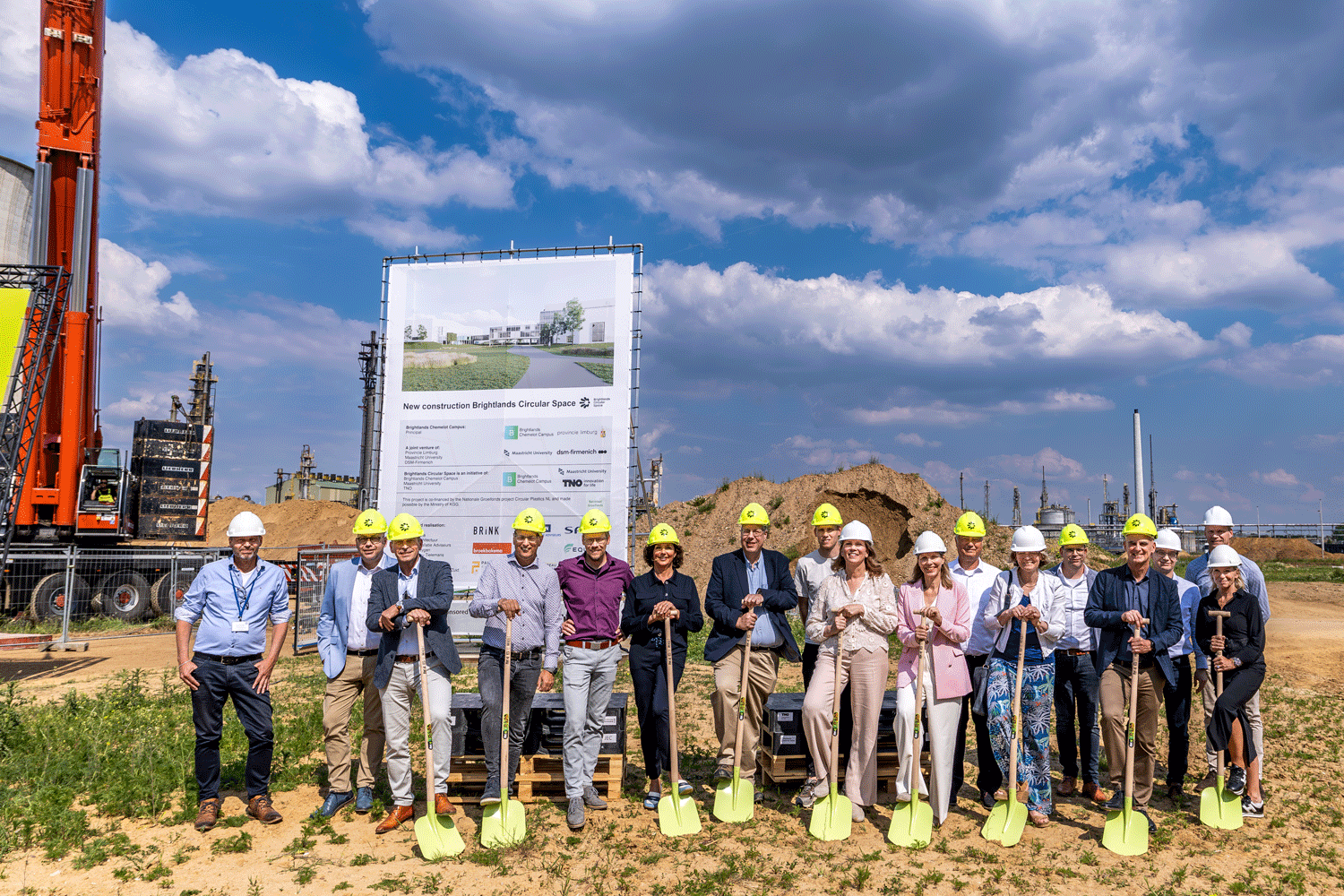

Construction has officially started today in Limburg of Brightlands Circular Space, a demonstration facility that accelerates the transition to circular plastics. This innovation site for the plastics of the future will be located on the Brightlands Chemelot Campus in Sittard-Geleen. Brightlands Circular Space is an initiative of Brightlands Chemelot Campus, Maastricht University and TNO. Completion of the world's first fully circular and open-access plastics demonstration facility is planned for 2026.

New steps in integrated approach sustainable plastic value chain

While the traditional way of making plastic is important for many products, it is necessary to make rapid steps toward a circular future for several reasons. Brightlands Circular Space aims to help producers, recyclers, designers and researchers find solutions for the future. In doing so, Brightlands Circular Space focuses on the entire plastic chain: from production and use to reuse and recycling. In it, we combine innovation expertise at the academic and applied level together with expertise in material analysis and upscaling.

Brightlands Circular Space will be an international hub where companies, knowledge institutions, policymakers and designers collaborate on sustainable innovations with plastics - from packaging to applications in cars, textiles and electronics. The facility will be open-access, offering space to develop new knowledge, test technologies, make products on a larger scale, create new jobs and try out new business models and collaborations. In this way, Brightlands Circular Space helps parties innovate faster, bring new solutions to market faster and reduce risks.

We are building a unique project for the plastics value chain, but actually building a place that is more than just a circular demonstrator. We are building a new story, showing that circular plastics is not just an ideal on paper, but really has a place in our common future. We are convinced that with this demonstrator we have something beautiful on our hands, something that can change the world of plastics."

Lia Voermans - Chair Steering Committee Brightlands Circular SpaceFour integrated facilities

The demonstration facility, located on the Brightlands Chemelot Campus, consists of four interrelated components equipped with state-of-the-art equipment and expertise:

- Circular House: a makerspace and meeting place for co-creation,

- material analysis, business models and valorization of circular innovations.

- Polymer Processing facility: focused on process optimization, new polymers and product testing.

- Plastic Waste Preprocessing facility: for high-quality preprocessing of plastic waste and improved quality of recyclate.

- Process Module (Skid), Pilot and Demonstrator Facility: where new technologies and processes can be scaled up.

Also read

-

More than another ‘to-do’: how the UTQ helped me rethink my teaching

At Maastricht University, the University Teaching Qualification (UTQ) is a professional development programme designed to strengthen teaching and learning. It supports teachers in developing core teaching competencies through a combination of workshops, peer learning, on-the-job experience, and...

-

MaaSec – The Netherlands' Only Active ACM Student Chapter captures the flag

In January, a group of Computer Science students at Maastricht University launched MaaSec, currently the only active ACM student chapter in the Netherlands. And in just a few months, they've already made a name for themselves; especially in the world of Capture the Flag (CTF) competitions.

-

Publication of the National Vision on Sustainable Carbon in the Chemical Industry

On April 22, the National Vision on Sustainable Carbon in the Chemical Industry was published for public consultation.