AMIBM surpasses all expectations

In 2016, the Aachen Maastricht Institute for Biobased Materials, AMIBM for short, opened its doors at Brightlands Chemelot Campus in Geleen. This cross-border institute specializing in the field of new biological materials is financed by universities and governments in Germany and the Netherlands and is staffed by researchers from both countries.

A courageous “experiment” facing many bureaucratic hurdles and uncertainties, over the past four years, it has served as the prelude to the creation of several cross-border research laboratories. “We've surpassed all of the expectations,” says managing director Richard Ramakers.

Richard Ramakers received the final confirmation in early January: the Province of Limburg will be investing four million Euros in AMIBM’s continued development. “Founding fathers” Maastricht University and RWTH Aachen University will continue to be responsible for part of the financing. This will ensure continuity for at least the next four years.

Positive mid-term evaluation

This is no surprise, according to the managing director who has been involved with the institute from the start. “The agreement was that we would conduct an in-depth evaluation after four years. This so-called mid-term evaluation in May 2019 was extremely positive, which is a prerequisite for continuation. We have performed above expectations for all of the benchmarks. There are a hundred people working here now, more than double our initial estimate. The number of scientific publications is higher than expected, several spin-off companies have formed, and our Biobased Materials master's program attracts students from all over the world. AMIBM has put itself on the map in record time, and not insignificant is the fact that it has ended up in a better position for finding additional sources of financing, such as national and European subsidies. So far we have already raised over 14 million Euros from other sources.”

Best of several worlds

AMIBM was founded to develop new materials for industrial and medical applications based on biological raw materials, one of the spearheads of Brightlands Chemelot Campus. “The starting point was the combination of the best of a few different worlds,” Richard Ramakers says, explaining the collaboration between the universities of Aachen and Maastricht at the campus. “The RWTH’s reputation for its strong position and various research groups focused on materials applications, the presence of various small and large producers here at Chemelot and the ambitions of Maastricht University with a new research group and Biobased Materials study program mean a huge concentration of knowledge, skills and facilities within a twenty kilometer radius. Uniting all these forces in a single institute could make us one of the trendsetting regions when it comes to the development of sustainable materials from biological sources such as plant-based residual materials.”

Bureacratic obstacles

It may sound like a great idea but setting up a cross-border institute also comes up against bureaucratic obstacles in the united Europe. “It wasn't an easy process,” Richard Ramakers acknowledges. “There are different social systems for cross-border workers. Cross-border funding by universities and public authorities involves very complex procedures, as does applying for European grants. You have to deal with certifications and so on. And then there are of course the cultural differences between the countries. We have put a lot of energy into ironing out all the problems, and after four years, I would even be so bold as to say that we have succeeded. In fact, we were even given the opportunity to provide an explanation in The Hague, Berlin and even at the European Commission in Brussels of how we managed it and why we were successful. A second team is now working on the formation of a second research institute, AMICARE, focused on the collaboration between Aachen and Maastricht in their work on heart and kidney diseases. AMICARE will be based at the RWTH campus, and there might be more “AMI” offshoots. We have proven that the model works.”

Combination of the practical and theoretical aspects ánd the focus on sustainability

Over the past four years, the number of AMIBM employees has grown to one hundred. They work in the labs and supervise students who come to Geleen from all over the world for the Biobased Materials master’s program, or to complete their bachelor thesis for the Maastricht Science Programme. The research is divided up into seven sub-areas. “We have achieved excellent results,” says Professor Stefan Jockenhövel, co-founder of the institute and now scientific director. “We conduct fundamental research, applied research and joint research with business. The combination of the practical and theoretical aspects and the focus on sustainability makes this place so attractive for both researchers and students. Sustainable, bio-based materials are a current theme. Romano Orrú, a renowned professor at the VU University Amsterdam, recently moved here to set up a research group on bio-based building blocks. It’s hard to imagine a better compliment than this.”

Promising projects

AMIBM is responsible for a constant flow of scientific publications. “And not just that,” Stefan Jockenhövel continues. “We also produce innovative and concrete new materials from biological raw materials. Just to mention a few examples: a transparent plastic made from sugar beet waste, and fibers made from a new polymer produced from lactic acid that bed manufacturer Auping can use in duvets. In the medical field, we are developing a biological, antibacterial coating for implants made from shrimp shells. We’re currently working on dozens of projects, each one of which is promising.”

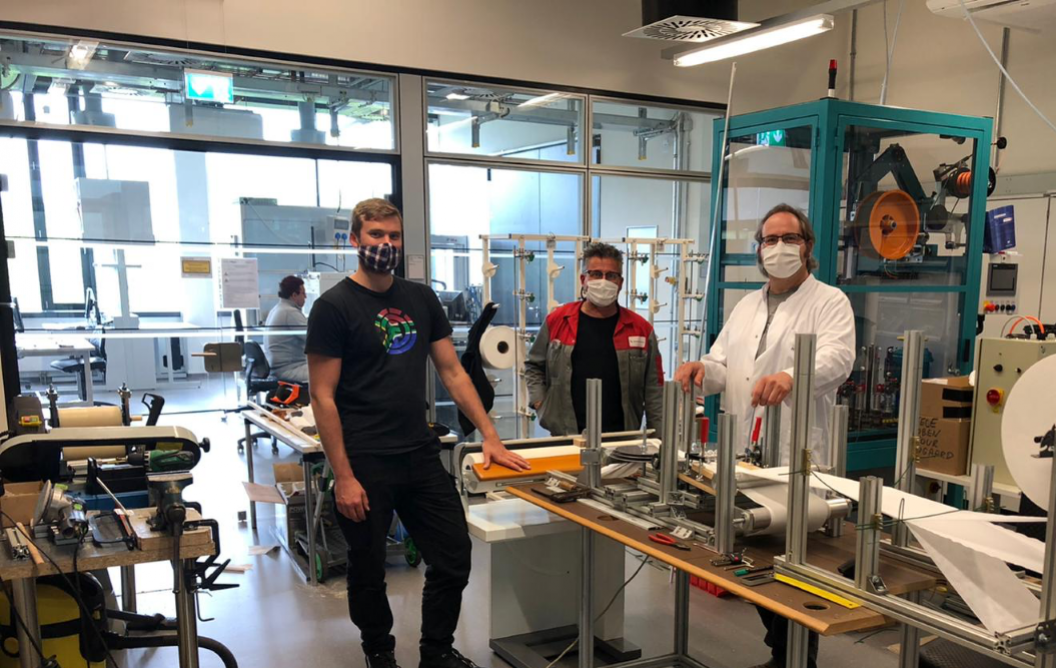

AMIBM and surgical masks

The corona crisis also brought the work in AMIBM’s labs at Brightlands Chemelot Campus to a standstill for two months. Behind the scenes, however, they’ve been working on a production line for making surgical masks and a machine to test the quality of these masks. The equipment is up and running at Boogaard Textiles in Wittem which normally produces pillowcases but is now producing surgical masks full-time. “Word-of-mouth led to requests to help the entrepreneur come up with ideas,” Richard Ramakers says. “We have designed and built a production line that is already capable of producing thousands of surgical masks per hour. Eventually, the company wants to make millions of masks. AMIBM wants to develop masks made from biodegradable materials. It’s a wonderful project; all of AMIBM's expertise comes together here to benefit SMEs. This is also how we’re contributing to fighting the crisis.”

Also read

-

Maastricht University and YERUN - A recap and a glimpse into 2024

Maastricht University is an active member of the Young European Research Universities Network, championing values of innovation, openess and responsibility.

-

Empowering Smallholder Farmers in the Data Economy: Unlocking Opportunities and Overcoming Obstacles

Frederik Claasen, the head of policy at our partner organisation Solidaridad Network on the opportunities and obstacles facing smallholder farmers in their data ecosystems.

-

How do involuntarily returned migrants fare in Senegal?

The PhD research of Karlien Strijbosch focuses on Senegalese migrants who were forced to return home after a stay in Europe. Doing justice to such stories is no easy feat, especially when you come up against walls of silence, distrust and shame. Strijbosch and her supervisor Valentina Mazzucato...