Department of Data Science & Knowledge Engineering co-operates in shaping the factory of the future!

In the past months, the Department of Data Science & Knowledge Engineering (DKE) has joined forces with several companies from Limburg in the area of industrial robotics with the goal of founding a new Fieldlab in Roermond, filled with state-of-the-art robotic equipment.

This robotic equipment will be shown to potential customers to facilitate cooperation on the topic “Factory of the Future”. The Fieldlab will also provide DKE students with access to cutting-edge robotic equipment from company partners that would be hard to access in a university environment.

Factory of the future

Factory of the future, Industry 4.0, cyber-factory or connected factory: Regardless of what it is called, this transformation of industry represents a revolution in manufacturing processes based on new technologies and innovative concepts.

Fieldlabs

Fieldlabs are environments in which companies and knowledge institutions develop, test and implement Smart Industry solutions, as well as an environment in which people learn to apply these solutions. They also strengthen links with research, education and policy on a specific Smart Industry theme. Some have a regional focus, others are national and even European focus.

To see the FieldLab and some of the DKE robots, see the TV report regional TV-channel L1

For more info on the initiative, visit https://www.smartindustry.nl/fieldlabs-2/

I am very proud to say that now through DKE SwarmLab, Maastricht University has a chair on the steering committee of this new Fieldlab Robotics which will hopefully offer many new opportunities for us.

Dr. Rico Möckel (Assistant Professor for cognitive robotics and intelligent systems director of DKE SwarmLab)

Also read

-

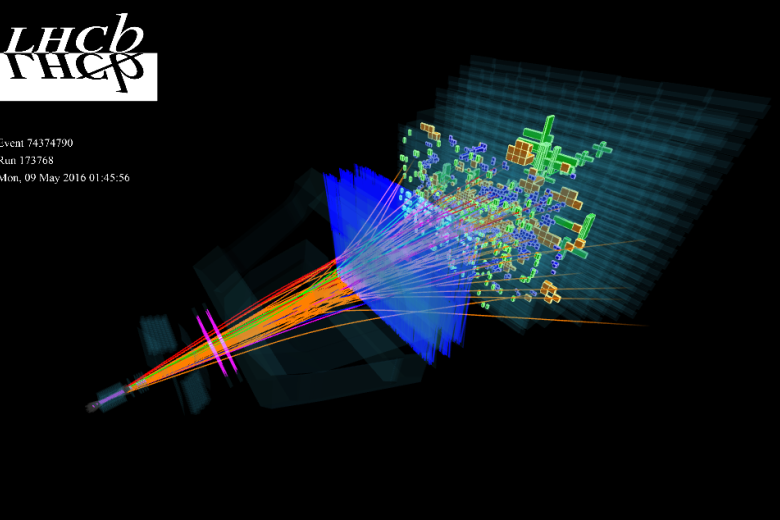

Maastricht University contributes to FASTTRACK: extremely fast particle detection at CERN.

Maastricht University is participating in the FASTTRACK project, which has been awarded a €21.7 million NWO Roadmap grant. FASTTRACK will enable extremely fast detection of particle collisions in the Large Hadron Collider.

-

Harm Askes: “Helping people excel, no need for showmanship.”

Harm Askes, the new vice-dean of FSE “Let’s continue building a faculty where talent shines: no ego, just impact, collaboration, and curiosity."

-

DigiMach: Digital Transformation of the Machining Value Chain for Sustainable Growth

DigiMach is a transnational 3-year collaborative approach that will transform manufacturing across the Meuse-Rhine region by bringing AI, IoT, and robotics to small and medium-sized enterprises in the machining sector. The project will assist more than 150 SMEs to adopt smart, digital tools, through...